|

| Fig: Lab Testing – (LT) |

Avron Texwear is driven by the maxim of achieving the desired quality at the most competitive prices, by employing on all available resources, controlling wastages, improving efficiency. We provide fast quotation service to our valued clients with all fabric and garment elements coasted in and detailed on a pricing matrix.Clothing Manufacturer Bangladesh We value our relationships with our Buyers and Vendors as a part of our business practices. We are bound to meet all of your expectations, and provides you an excellent experience in doing business with Bangladesh.

Yes, Avron Texwear. is Buying Office in Bangladesh & for reliability and a trustworthy, positive account .

Quality Assurance

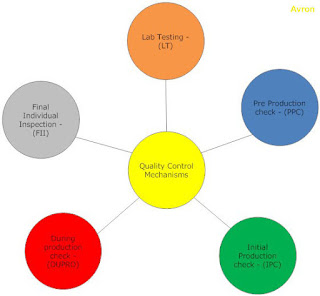

Quality Control Mechanisms: Synonymous with quality, our products constantly set new standards for excellence within the industry. The cornerstone of our success, quality - is of paramount importance to us altogether our operations. Through a strict regimen of quality checks & controls, we maintain a consistency within the quality of raw materials procured, within the quality of our manufacturing work, in packaging, in Shipment & Service etc.

To ensure the very best quality of products, we follow 5 Level

Laboratories are a particularly valuable component of our services and also facilitate the manufacturers – exporters & importers to conduct their business with least quality risk. Our laboratory service includes.

Risk are reduced by inspecting accessories , performing Color Matching checks, Fabric Inspection, Lab dip testing, Daily Cutting checking, Wash testing, Knitting & Flannel Inspection, Measurement Spec checking.

First finished products are checked against buyer’s specifications and a prototype sample. clothing manufacturers in Bangladesh Deviations are identified and corrected.

Inspection during production is administered to see and verify that the initial discrepancies are rectified and to make sure the simplest quality standard of production runs.

Final individual inspection is administered when the entire consignment is packed and prepared for shipment. FII is performed according to international inspection standards. The detailed physical inspection of the samples selected individually is based on specification of the buyers and it cover criteria such as design/ style, shrinkage, accessories, appearance, marking, colors, labeling, material, assortments, workmanship, measurements and packing. Hence, Our Quality Assurance has been much admired & respected by our Buyers world-wide.

Pre Production check – (PPC)

Initial Production check –

(IPC)

During production check – (DUPRO)

Final Individual Inspection - (FII)